For a large number of users with rigid demands on polarized strain viewer, it is clear that the testing principle is a prerequisite for performing measurement work and improving the production process. Some customers have not been affected by the testing principle and operation method of the polarized strain viewer even after it has been purchased and used for a period of time, which affects the performance and testing results of the instrument.

The testing principle of the Polarized Light Strain Viewer is as follows:

The stress value of the glass product is accurately tested, and the core component of the glass product is the built-in light wave plate of the stress meter. At the beginning of the test, the light wave plate can use the principle of diffuse reflection and refraction of light to perform birefringence after the glass product is brought into the glass product by the light source, thereby entering people's eye. The stress difference of each part of the glass product cause path differences in the eye of the daylighter, and create optical path differences in the middle.

Steps:

(1) Turn on the power and the switch, the light will be on.

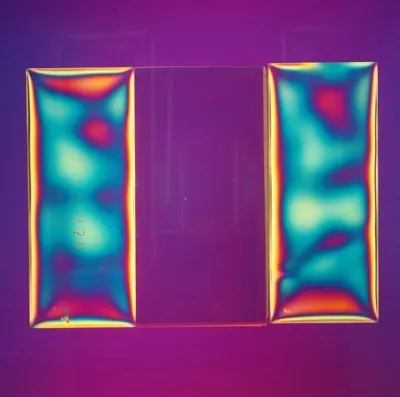

(2) Place the glass product between the analyzer and the polarizer of the instrument.

(3) The examiner looks down from the top of the analyzer, and can observe the stress in the lens circle around the lens.

(4) According to the observed stress situation, determine whether the stress around the lens is uniform or the parts that need to be corrected.