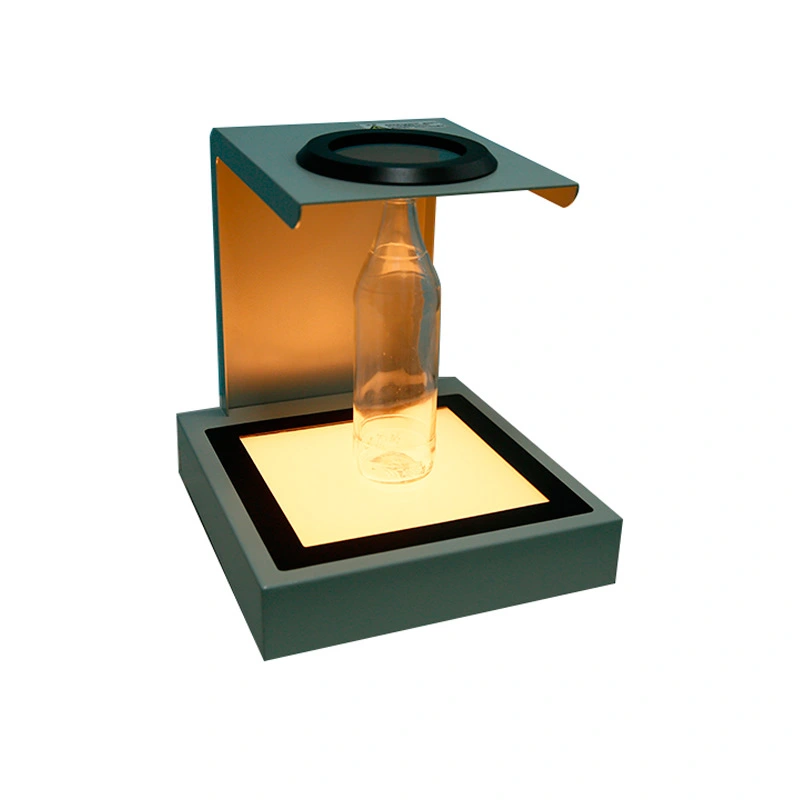

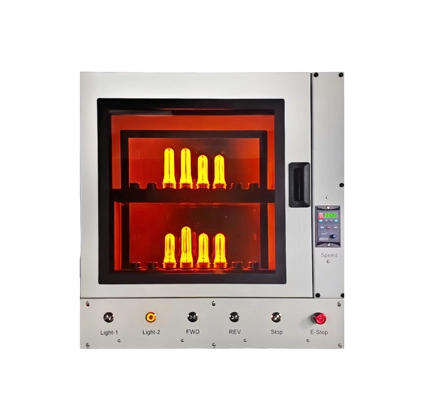

Polarized light is adopted to observe and analyze the internal stress of transparent glass and plastic products. This method often referred to as photoelasticity, involves passing polarized light through a transparent sample and analyzing the resulting light patterns to detect stress distributions within the material. This device is an essential tool for industries where material integrity of glass and plastic components is critical, such as in automotive, aerospace, and consumer electronics manufacturing. Its ability to provide detailed insights into material stress makes it invaluable for maintaining high-quality production standards.

EN

EN

ko

ko  fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  hi

hi  jw

jw  zh-CN

zh-CN