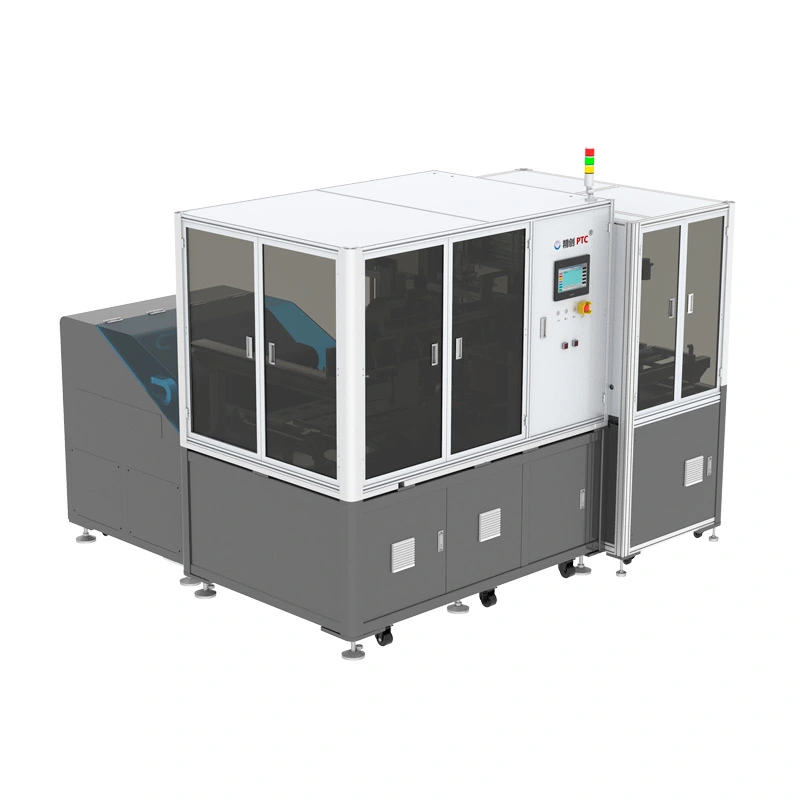

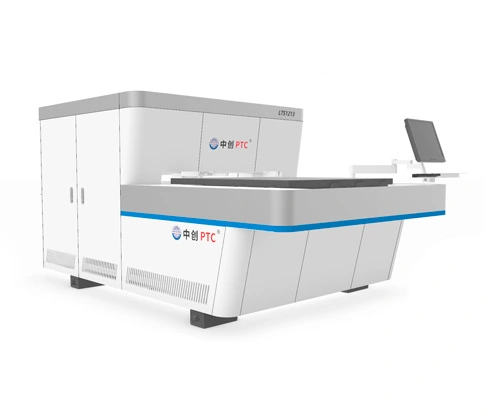

Scanning acoustic tomography equipment is designed with core acoustic microscope, automatic loading, unloading and intelligent inspection algorithm. The scanning acoustic microscope adopts multiple probes to scan multiple products in parallel. It can clearly display the structure of multiple layers on the surface and internal of the product at the same time.

Moreover, scanning acoustic microscope is intelligently analyzes the image of each layer to automatically identify and locate the defect position. Common defects include voids, delamination, folds, cracks, etc. And the size and area of defects are counted, recorded, stored, and marked. Thus users can accurately sort defect products, and can automatically generate statistical reports, which is convenient for customers to carry out quality management and control.

EN

EN

ko

ko  fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  hi

hi  jw

jw  zh-CN

zh-CN