Lenses are an important component of optical imaging systems. Taking VR AR imaging system as an example,residual stress in the lenses will have the following two negative effects.

Lens stress can cause optical distortion, which changes lens shape and surface accuracy , thereby affecting the imaging quality of optical equipment. Stress will cause bending and distortion of the lens, resulting in aberrations, making the light unable to focus, thus reducing the clarity and resolution of the image. In addition, lens stress can also cause the dispersion effect of optical equipment, leading different transmitting speeds of light with different wavelengths in the lens, finally resulting in the generation of chromatic aberrations.

Lens stress can cause changes in the shape and size of the lens, which can affect the stability of the optical device. Stress will deform the lens, causing the optical reflection effect on the lens surface to change, thereby affecting the transmission and reflection of the optical path. Stress will also cause changes in the microstructure of the lens material, causing changes in the refractive index and dispersion properties of the lens, thereby affecting the propagation of light and imaging effects.

Commonly used lens stress measurement methods include optical, mechanical and thermal ways. The optical method uses the principle of photoelasticity to measure the phase difference (optical path difference, optical retardation) to indirectly reflect the existence and magnitude of stress. The fully automatic Polariscope launched by Suzhou PTC Optical Instruments can help lens manufacturers quickly and accurately measure the optical retardation caused by stress inside lenses.

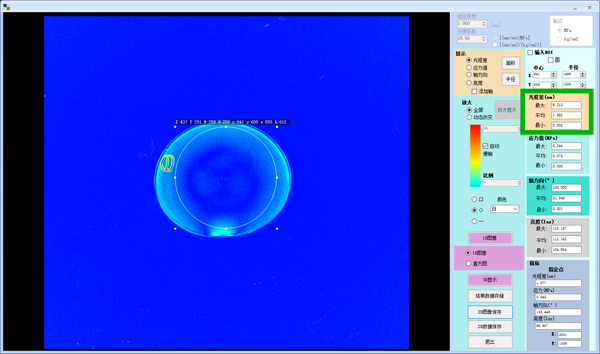

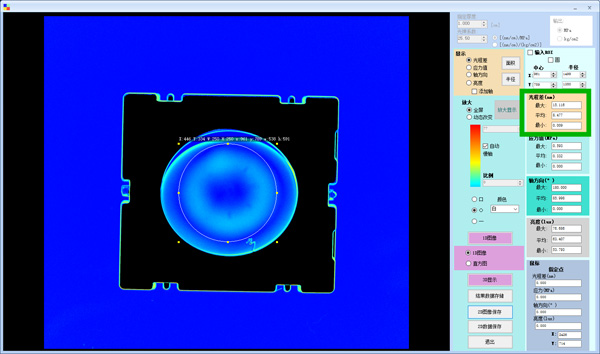

In below figures , lens stress before mounting and after mounting are demonstrated.

Optical retardation before mounting (max: 6.213nm, ave: 1.882nm)

optical retardation after mounting (max: 15.116nm, ave: 8.477nm)

It is not hard to notice that additional assembly stress is introduced during the mounting process. By optimizing the blessing power, support methods and installation process, assembly stress can be decreased largely .