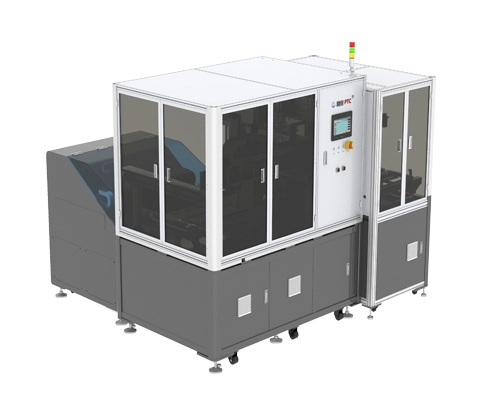

This automatic defect inspection equipment uses a multi-station optical imaging system to capture the imaging of the sample boards. Specific algorithm processes the acquired images to capture the defects. This automatic equipment can not only effectively improve the detection efficiency, but also greatly reduce the missing rate. Defects inspected by the equipment include protrusion, residual copper, cutting dislocation, poor solder mask, oxidation, scratches, copper deficiency, bubbles, poor plating and others.

EN

EN

ko

ko  fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  hi

hi  jw

jw  zh-CN

zh-CN