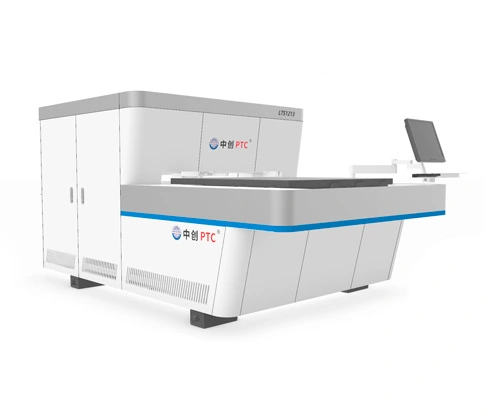

This auto optical inspection machine is an automatic system for AMB defect terminal inspection, including loading machine, AOI machine, unloading machine and workstation. This automatic optical inspection equipment can greatly improve the product detection rate, thereby improving production efficiency for enterprises and save production costs, realizing one-stop automatic operation.

The AOI machine adopts two-station design to scan the upper and lower surface with the incoming products, and inspects various defect sizes and marks defect position coordinates, judges OK and NG products automatically, then sorts them into different ports of the unloading machine. User can review product inspection data and defect map information at the workstation, which greatly facilitates product inspection status analysis and re-inspection.

EN

EN

ko

ko  fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  hi

hi  jw

jw  zh-CN

zh-CN