Screen printing has long been a staple of the printing industry, offering vivid color application on a variety of surfaces. However, achieving high-quality results consistently requires precision and reliable equipment. This is where PTC comes in. PTC provides state-of-the-art solutions, including Screen Printing Frame Stretching Equipment, Screen Printing Mesh Hot Melt Machine, and Printing Screen Integrated Inspection and Rework Equipment. In this blog, we will explore how each piece of equipment can elevate your screen printing process.

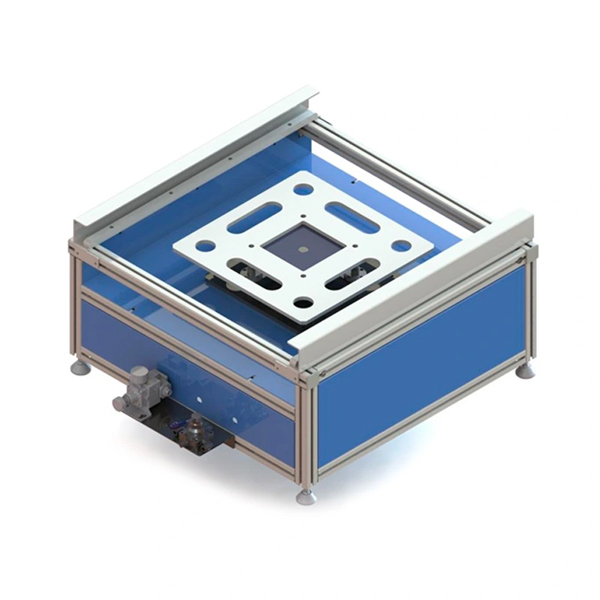

One of the fundamentals of successful screen printing is having a properly stretched screen frame. PTC’s Screen Printing Frame Stretching machine is engineered for optimal precision and durability. Poorly stretched screens can lead to print quality issues, such as misalignment and uneven ink distribution. PTC’s system ensures that screens are stretched to the perfect tension, providing a firm and consistent print area. This minimizes errors and reduces waste, leading to cost savings and improved production efficiency.

Benefits:

1. High precision stretching for consistent print quality.

2. Durable construction built for long-term use.

3. Easy-to-use interface for quick setup and adjustments.

Once your screen frame is stretched perfectly, the next step is to ensure that the mesh is securely bonded. PTC’s Screen Printing Mesh Hot Melt Machine offers a reliable and efficient solution for this critical process. This machine utilizes advanced hot melt technology to create a strong bond between the mesh and frame, eliminating the risk of mesh slippage during printing. A well-bonded screen ensures sharp, clear prints and reduces downtime caused by frequent adjustments or replacements.

Features:

1. Advanced hot melt technology for secure mesh bonding.

2. Quick setup time for increased productivity.

3. Consistent results to maintain high-quality standards.

Despite the best preparation, occasional errors and imperfections can still occur. Ensuring that each screen meets your quality standards before printing is essential. PTC’s Printing Screen Integrated Inspection and Rework Equipment is designed to detect and address these issues efficiently. This equipment allows for thorough inspection and easy rework of any detected flaws, ensuring that only the highest quality screens are used in the production process.

Advantages:

1. Advanced inspection capabilities to identify minor and major flaws.

2. Streamlined rework process to correct issues promptly.

3. Improved overall print quality and reduced waste.

Investing in high-quality screen printing equipment like PTC’s Screen Printing Frame Stretching Equipment, Screen Printing Mesh Hot Melt Machine, and Printing Screen Integrated Inspection and Rework Equipment can significantly improve your production process. These machines provide precision, efficiency, and quality assurance needed to produce superior prints consistently. Whether you are a small business or a large-scale operation, incorporating PTC's solutions can lead to better results, higher customer satisfaction, and increased profitability.

In the competitive world of screen printing, don't settle for less. Choose PTC for reliable, state-of-the-art equipment that will transform your printing process and elevate your business to new heights.