Glasses are used in numerous applications and have a significant use to produce domestic goods and many industrial products like glass windows, panels, glass utensils, and many more.

However, the existence of internal stress in glass will affect the mechanical properties and use of the product. In severe cases, it will damage the product and hurt the users indirectly. Besides, its existence will reduce the product's resistance to light, heat and corrosive media, and affect processing and reducing product yield. At the same time, the product will appear cracks, irregular deformation and warpage during use, and the surface of the product will be white, turbid, and can decrease in the optical performance as well.

If the inferior glass bottle is heated, it will be broken and damaged when the bottle suddenly cool down. This is due to the existence of stress inside the glass, which we cannot observe visually. Therefore, we need to use professional instruments to detect and analyse the internal stress, and apply it to production activities.

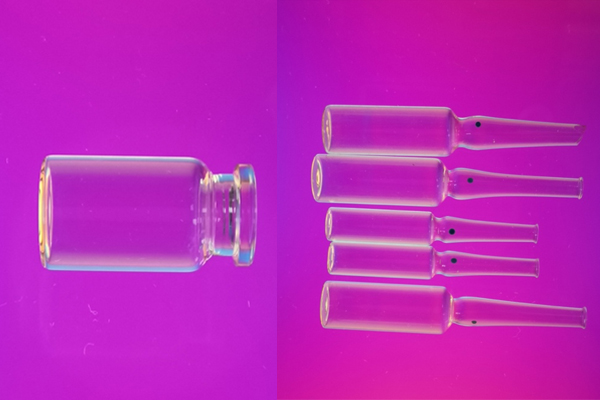

PTC Optics offers Glass Stress Meter to test the internal stress and surface stress of the glasses, and the stress will be displayed by colour distribution. Glass products can be easily rejected by the manufacturers if the desired stress value is too large. The testing machine plays a significant role to view the strains in the glass materials, such as: ampoules, medicinal bottles, glassware, wine bottles.

Glass Stress Meter also known as Polariscope, which is the best testing machine that protects the quality of the glasses from various quality flaws that can occur at the time of manufacturing or designing process. It is a very effective testing machine that helps to judge the strains on the material surface under the polarized light. The testing machine helps to detect the microscopic defects that are present in the glasses.

Visit www.ptc-stress.com for more information on Polariscope Strain Viewer.