In today's rapidly advancing technology, circuit boards, as the core components of electronic devices, are of undeniable importance. From the "green board" we stumbled upon when dismantling toys as children, to today's highly integrated and complex printed circuit boards, they are not only sturdy carriers of electronic components but also the key driving forces behind technological progress. Among the many circuit board materials, ceramic substrates stand out with their unique performance advantages, shining brightly in front-line fields such as 5G communication, new energy electric vehicles, the Internet of Things, wind power generation, and military aerospace. However, as application areas expand, the quality requirements for ceramic substrates are becoming increasingly stringent, making the detection of internal defects a crucial process. At this point, PTC's scanning acoustic tomography, with its excellent performance, becomes a reliable assistant for detecting defects in ceramic substrates.

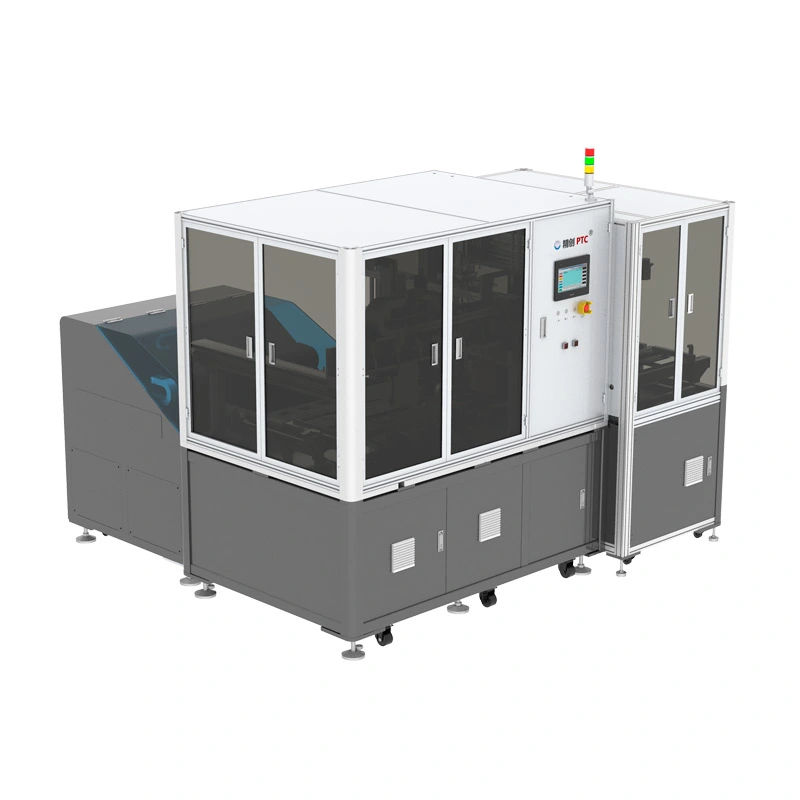

Facing defects such as voids, delamination, folds, and cracks that may exist inside ceramic substrates, traditional detection methods are often inadequate. PTC's scanning acoustic tomography, with an ultrasonic microscope at its core, achieves clear display of both the surface and internal multilayer structure of the product. By utilizing multiple parallel scanning probes, this equipment can quickly capture and present every detail of the ceramic substrate, ensuring no omissions.

PTC's scanning acoustic tomography not only has strong scanning capabilities but also features built-in intelligent detection algorithms. These algorithms can automatically analyze scan images, accurately identifying and locating defect positions. Whether it's a tiny void or a complex crack, nothing escapes its "sharp eyes". Additionally, the equipment can precisely count, record, store, and mark the size and area of the defects, providing users with comprehensive and accurate data support.

To further enhance detection efficiency, PTC's scanning acoustic tomography can be equipped with an automatic loading and unloading machine, achieving a fully automated process for loading, scanning, inspecting, and unloading. This design significantly reduces the burden of manual operations and remarkably increases detection speed and accuracy. Moreover, the equipment supports intelligent recipe scanning and detection modes, capable of flexibly adapting to the needs of different types and specifications of products, providing users with more convenient and efficient detection solutions.

PTC understands that each customer's needs are unique. Therefore, we offer comprehensive customization services, from equipment selection to function configuration, and software upgrades to after-sales service, all tailored to your specific requirements. Whether you need a detection solution for specific defect types or wish to achieve seamless integration with existing production lines, PTC's scanning acoustic tomography can meet your needs.

In summary, PTC's scanning acoustic tomography, with its outstanding performance, intelligent analysis capabilities, and efficient automated process, provides robust technical support for detecting internal defects in ceramic substrates. In future developments, we will continue to uphold the concepts of innovation, pragmatism, and efficiency, offering high-quality detection solutions to a wider range of industry sectors.