Always wear appropriate protective gear, such as gloves and safety glasses, to prevent injuries from broken glass or sharp edges.

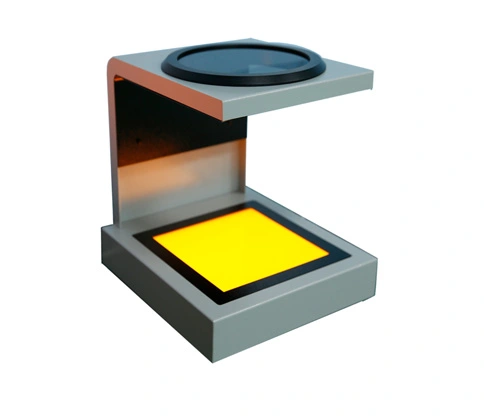

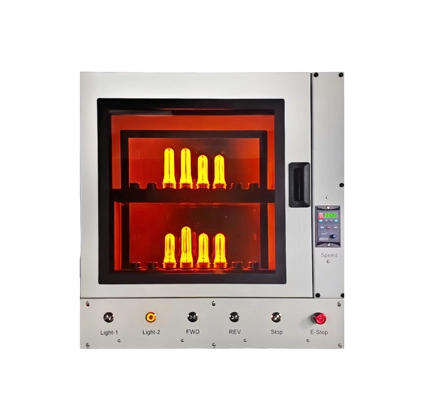

Strain viewer is an essential tool in quality control and material testing for transparent materials like glass and plastics. Polariscope strain viewer works by using polarized light to reveal stress patterns within the material. When the material is placed between two polarizing filters, any internal stress will alter the light's polarization, creating visible patterns or colors that indicate the presence and distribution of stress. This non-destructive testing method is particularly useful in industries where the integrity of transparent materials is critical, such as in the manufacturing of optical components, safety glass, and plastic products. By identifying areas of stress, manufacturers can address potential weaknesses or defects before the product is put into use, ensuring higher quality and safety standards. PTC’s advanced Polariscope Strain Viewer utilize polarized light for precise stress analysis, making PTC a leader in stress detection technology.

EN

EN

ko

ko  fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  hi

hi  jw

jw  zh-CN

zh-CN