With the continuous development of the market, lens technology is becoming more and more widely used.

Lens is an optical element made of transparent substances (such as glass, crystal, etc.) that affects the wavefront curvature of light. It can aggregate or disperse light, and the images formed includes both real images and virtual images. Widely used in security, car wear, digital cameras, lasers, optical instruments and other fields. Various ordinary colorless optical glasses including fused silica, calcium fluoride, magnesium fluoride, silicon, germanium, zinc selenide and other materials; and various wave bands of plano-convex lenses, biconvex lenses, plano-concave lenses, biconcave lenses, super hemispherical lens, small spherical lens, meniscus lens, cylindrical lens, rod lens, cemented lens, etc.

Lenses are made according to the refraction laws of light. Lens is a refractor whose refraction surface is a transparent body with two spherical surfaces (part of the spherical surface), or a spherical surface (part of the spherical surface) and a plane. It has both real and virtual images.

The lens is the most basic optical element that constitutes the optical system of the microscope. The objective lens, eyepiece and condenser lens are all composed of single or multiple lenses. According to their different shapes, they can be divided into convex lenses (positive lenses) and concave lenses (negative lenses).

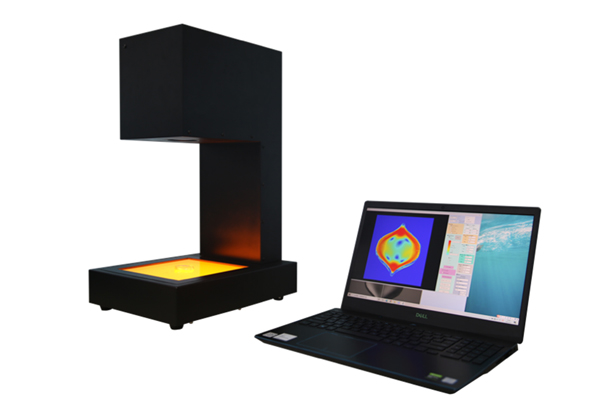

The stress requirements of the lens are very high. The fully automatic polarimeter NMV-145 developed by Suzhou PTC Optical Instrument Co., Ltd. is a two-dimensional quantitative measurement device that fully automatically detects the optical path difference and slow axis direction inside a transparent object with stress and birefringence. The repeated measurement accuracy of this device is up to 1um.

One-key automatic stress measurement within the whole viewing field;

The axial direction of the stress at each point can be displayed together with the internal stress value, which is convenient for stress type analysis;

The result is displayed in 3D mode, which visually displays the stress level if each point;

Eliminating environmental errors by calibrating under background light;

The high-speed and standard measuring modes can be switched freely to control detecting speed;

Using area array LED light source, and the brightness difference between center and edge is ≤ 20%.