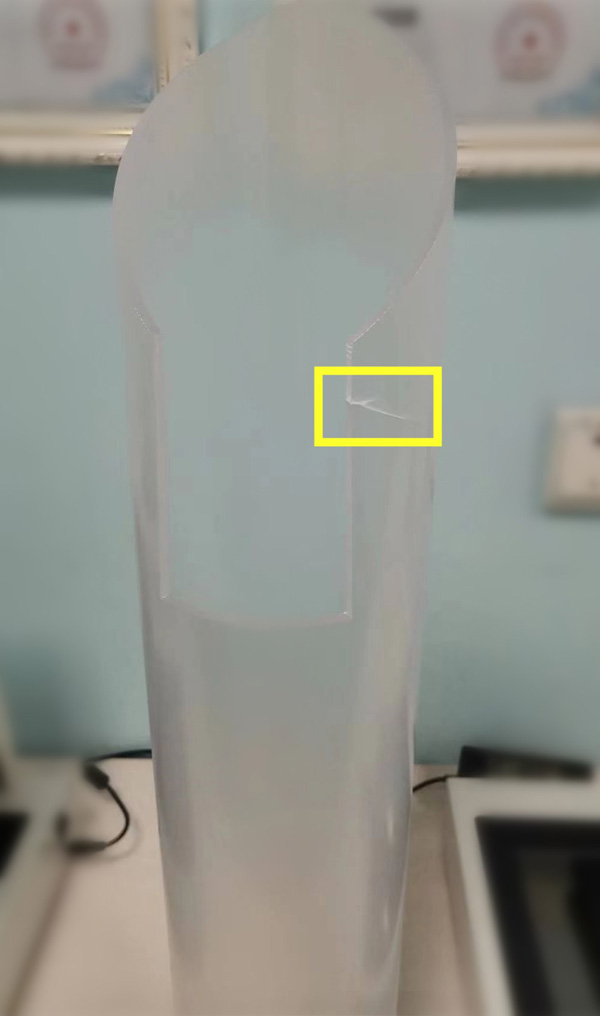

Testing stress (such as molded parts and thermoformed products ) in polycarbonate is crucial for several reasons:

Environmental Stress Cracking Resistance: testing helps evaluate the material's resistance to environmental stress cracking, a critical factor for durability. Polycarbonates are known for their high impact resistance and dimensional stability, making stress testing vital for ensuring these properties.

Mechanics and Behavior Analysis: stress-strain behavior analysis, especially under different conditions like strain rate and temperature, provides insights into the mechanical properties of polycarbonate. This is crucial for predicting its performance in real-world scenarios.

Design Data from Stress-Relaxation Tests: stress relaxation testing helps gather design data for polycarbonate, aiding in understanding its inelastic equation of state at various temperatures.

Tensile Strength Evaluation: tensile strength testing is often used as a basic determiner of a material's ability to withstand stress. This is crucial for assessing the overall strength and durability of polycarbonate sheeting.

Prevent Stress Cracking: this testing helps identify the propensity of polycarbonate to craze and crack under specific conditions, such as exposure to sunscreen. This knowledge is vital for preventing stress-related failures in practical applications.