PET preforms have been the most important semi-products for food and beverage industry. After blowing , they will be processed into various bottles and containers. Many preform manufacturers claim that there are some obvious defects on their bottles. There is a easy-operating and low-cost method to avoid such quality problem.

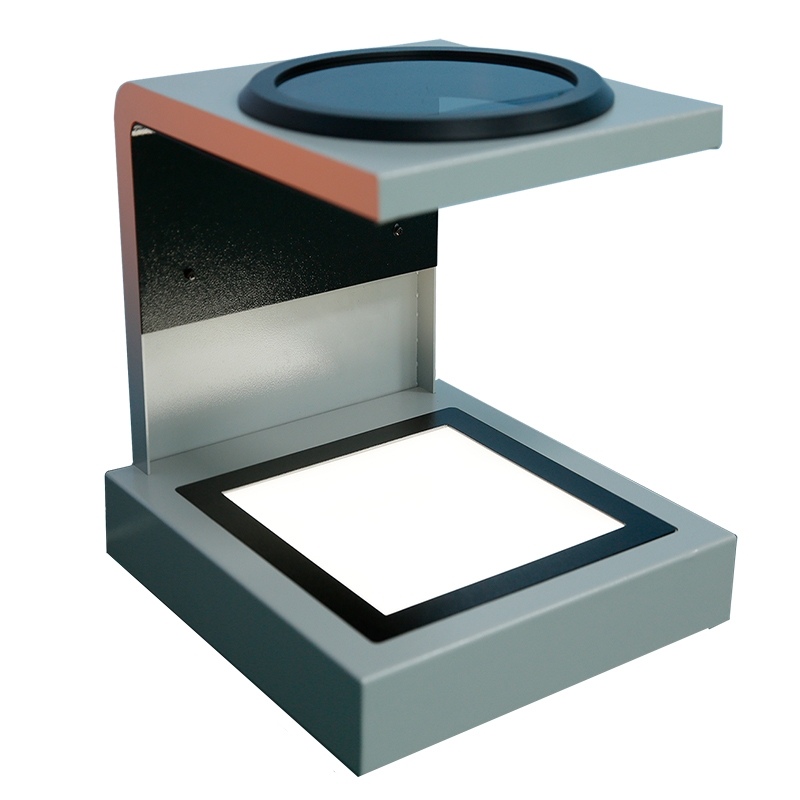

It is to use a non-destructive testing instrument ----Preform Polariscope. A polariscope takes advantage of polarizing light . When inspecting a preform under polarized light, the stripes ( patterns ) caused by molecular orientational strain becomes visible. These patterns are an excellent indication of preform quality when considered along with other defects which are more clearly under polarized light.

A well-made preform will display orderly stress patterns , while irregular stress patterns indicate a poorly made perform. So a preform polariscope is an practical testing instrument to pre-judge unqualified preforms. To ensure an even consistent material distribution throughout the bottle walls during blowing process , it is important to use a well-made perform.

Defects such as crystallization are usually invisible under natural light source, but they can be much clear when observing under polarized light.When placing a preform on a strain viewer, the angle at which the preform is placed relative to the polarization axis is very important .

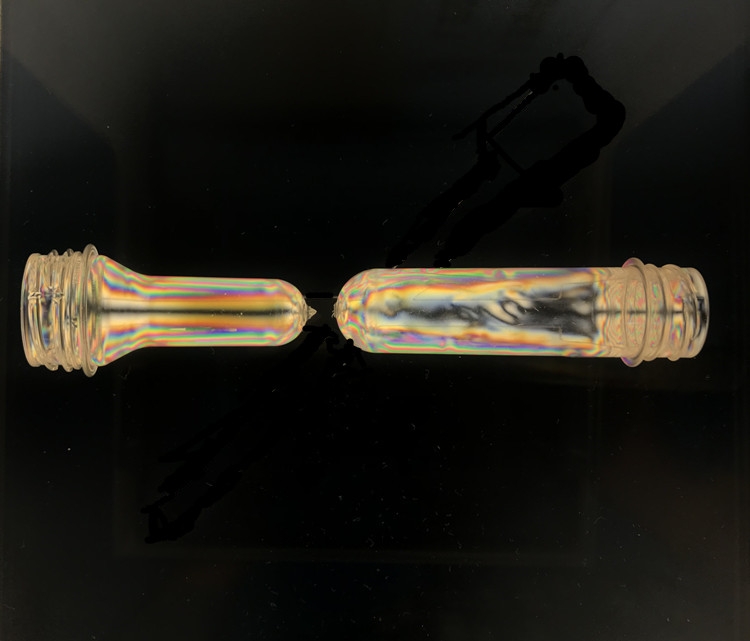

We usually choose to observe a preform when it is placed at 0°and 45°to the polarization axis.

1.When the preform is placed at 45° to the polarization axis, we will see two images

①Colored stripes in the sides of the preform. They are called isochromatic lines .

②A black line in the middle of the preform, which is called an isoblique line. It indicates the direction of stress.

2.When the preform is placed at 0°, only the isochromatic line can be observed. We will see a clear black pattern in the center of the preform.

For coloured performs such as amber, blue and etc , it will often be essential to use the yellow LED light.