Controlling glass stress is an extremely important part of the glass production process, and the application of appropriate heat treatment to control stress is well known to glass technicians. However, how to accurately measure the glass stress is still one of the difficult problems for the majority of glass manufacturers and technicians, and the traditional empirical estimation has become increasingly unsuitable for the quality requirements of glass products in today's society.

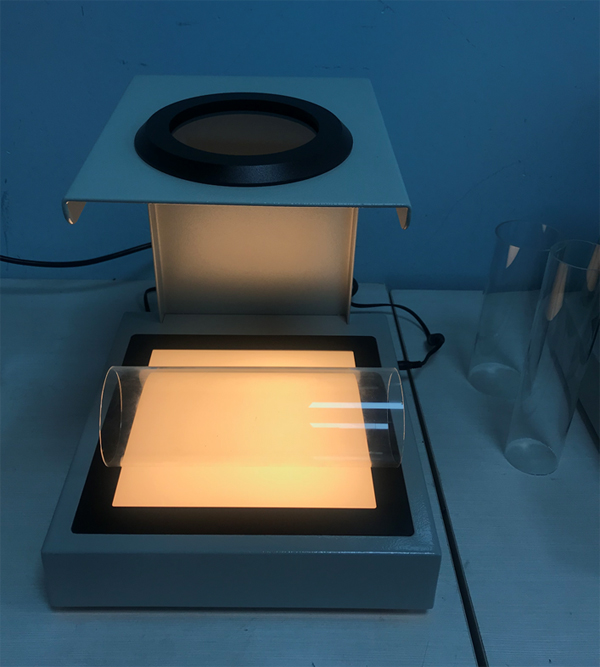

It is well known that light is an electromagnetic wave that vibrates in a direction perpendicular to the direction of progress and vibrates in all vibration planes perpendicular to the direction of progress. Polarized light can be obtained by introducing a polarization filter that only allows light in a certain vibration direction to pass through the optical path, which is called polarized light for short. The optical device made according to this optical characteristic is a polariscope.

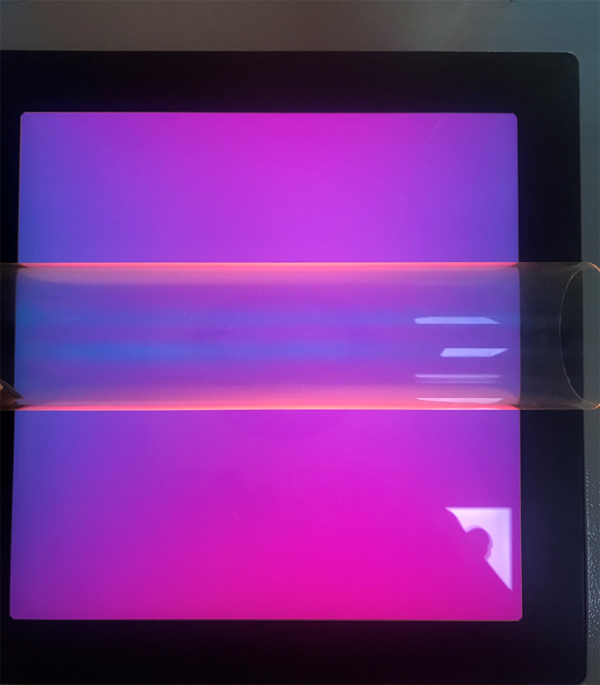

Glass is an isotropic body with the same refractive index in all directions. If there is stress in the glass, the isotropic property is destroyed, which causes the refractive index to change, and the refractive index of the two principal stress directions is no longer the same, which leads to birefringence.

When polarized light passes through a stressed glass of thickness t, the optical vector splits into two components that vibrate in the x and y stress directions, respectively. If vx and vy are the velocities of the two optical vector components respectively, the time required to penetrate the glass is t/vx and t/vy respectively, and the two components are no longer synchronized, there is an retardation δ.