PET bottles have strong applicability and are widely used in daily necessities, daily chemical packaging and other fields. PET preforms are processed by blow molding to form plastic bottles. This bottle-making method is called a two-step method, that is, a method of forming a preform through injection molding, and then forming a PET plastic bottle through blow molding. Therefore, the quality of plastic preforms will affect the quality of plastic bottles to a large extent. The internal stress of plastic preforms is an important detection index, which requires manufacturers to carry out labeling and control. Only in this way can the plastic bottles be put into the packaging of medicines, foods, and beverages in the later stage.

1.Polariscope for PET preform and equipment application

Suzhou PTC Optical Instrument Co., Ltd provides the polariscope (PSV-801) to detect the stress of transparent plastic products. This equipment uses the polarization principle to make qualitative observation and analysis on the internal stress of transparent PET preform, which can be displayed clearly and intuitively. It is widely used in the quality control of PET rough processing products, which is convenient for users to control the stress of their products in a timely, which helps to ensure and improve product quality.

2. Equipment Features

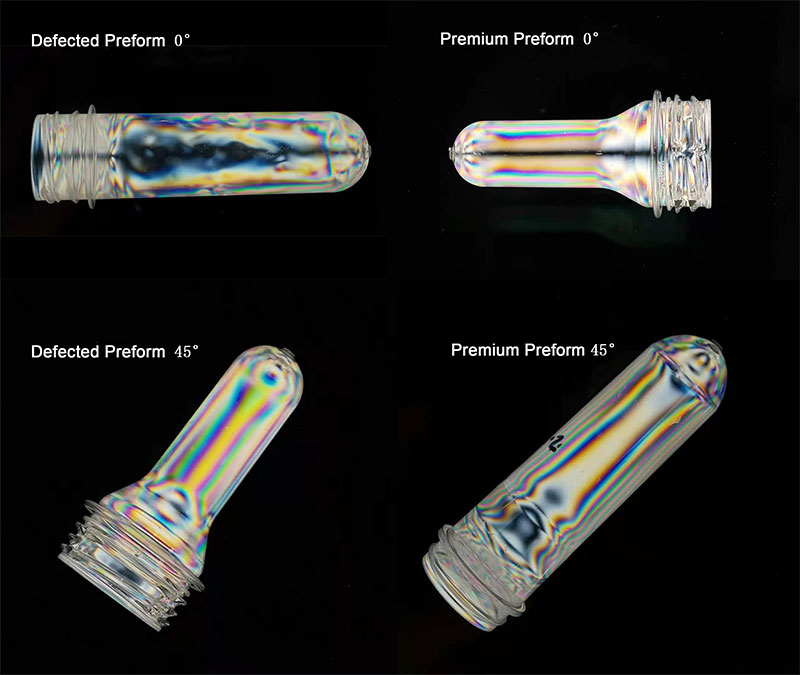

1) Defects invisible to the naked eyes such as crystallization or other common defects become visible;

2) When the plastic preform is placed on the Polarizer at a 45° angle, the colored birefringent stripes at the edge of the preform can be observed;

3) When the plastic preform is placed on the polarizer at a 0° or 90° angle, black birefringence stripes in the central part of the preform will be displayed;

4) In addition to white light, Sodium light is also used to test colored preforms or finished bottles;

5) Besides, this Strain Viewer provides 12 kinds of defect analysis functions.

12 kinds of colored defect comparison pictures will be attached to instruct related improvements in preform production process.