Glass jars are a kind of universal packaging containers, which are widely used for beverages, food, alcohol, chemicals, medicines, and cosmetics packaging. Compared to other materials such as PET, they are easy to clean, rich in style and decoration. Even in long-term storage, they will not pollute the contents. However, glass bottles are easy to break, and this shortcoming is gradually improving with the development of technology.

Glass bottle manufacturing process mainly includes batch preparation, melting, forming, annealing, surface treatment and processing, inspection and packaging.

The glass bottle has undergone drastic temperature changes and viscosity changes during the molding process. During the molding process, because the glass is a poor conductor of heat and has poor thermal conductivity. The temperature gradient and hardening speed of the inner and outer layers are different, which will cause uneven internal stress inside glass jars. This uneven internal stress is called thermal stress. This thermal stress will reduce the strength and thermal stability of glass products. If it is directly cooled, it is likely to rupture itself during the cooling process or later storage, transportation and use. Therefore, the glass product must be annealed after being formed.

Annealing of glass products is a process to eliminate and weaken the thermal stress of glass to a large extent. That is, use an appropriate temperature system to continuously lower the formed glass to room temperature. In this way , the residual stress in glass is reduced to the allowable range to strengthen glass mechanical strength and thermal stability. Annealing in glass bottle factories is mainly divided into two aspects: one is the weakening and eliminating of internal stress, and the other is to prevent the re-generation of internal stress.

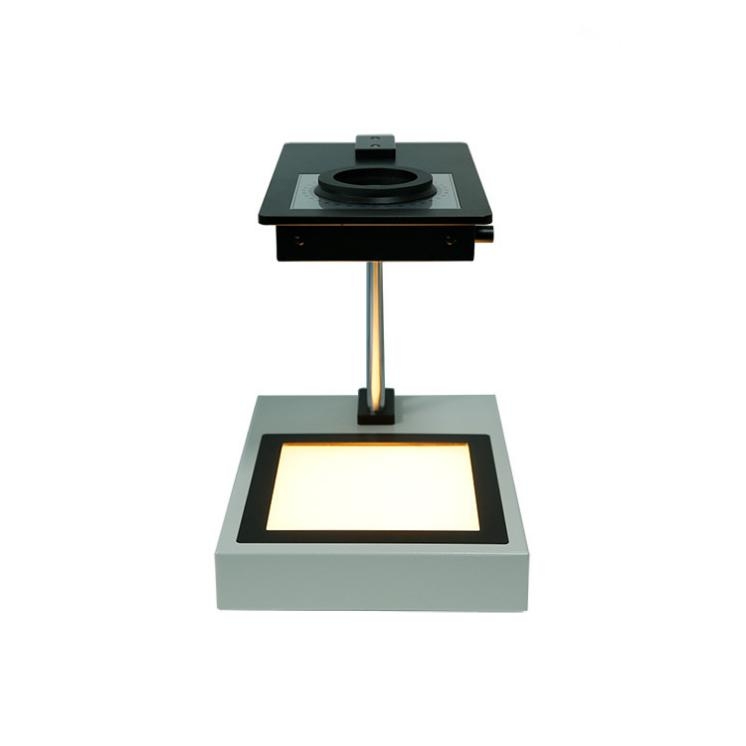

A specialized optical instrument will need to be applied to achieve this. That’s a Glass Bottle Polariscope .

Generally, a glass Polariscope is made of two parts . An analyzer on the top and an Polarizer on the bottom. The sample will be placed on the Polarizer . When proceed testing, we need to observe the viewing field from the Analyzer.

In the below, we will introduce how to use a glass container Polariscope according to Standard ASTM C148-17. This international standard has been developed in accordance with internationally recognized principles on standardization.

Requirements with Glass bottle Polariscope

1. The degree of Polarization of the field should be at all points not less than 99% .

2. A quarter-wave plate with an optical retardation of 141±14nm shall be inserted between the specimen and analyzer with the slow axis aligned with the plane of polarization of the Polariscope. The brightness of the Polarized field illuminating the sample shall be a minimum of 300 cd/m2.

3. The analyzer shall be mounted so that it can be rotated with respect to the Polarizer and the quarter-wave plate and the angle of rotation determined .

4. Samples must be allowed to cool until the entire thickness of the glass is at room temperature .

Measurement Procedures

1. Rotate the analyzer initially so as to have the analyzer plane of polarization perpendicular to the polarizing plan of polarization . This is the zero position in which the viewing field should at maximum darkness.

2. Put the container to be examinated in the viewing field with the tint plate in position .

Rotate the container to determine the location of the highest order retardation color at the inside of knuckle position .

3. Remove the tint plate. View the inside container bottom. A darkened extinction cross will appear in the container bottom, with lightened areas between the mutually perpendicular ,darkened legs of the cross . In containers having a low retardation , the extinction cross will appear to be hazy and indistinct . The extinction cross will appear to be colored magenta if the container is being observed in a sensitive tint plate Polariscope .

4. Rotating the analyzer causes the darkened extinction cross to separate into two darkened arcs which move outward in opposite directions toward the inside knuckle of the container. As the two arcs move outward , they develop a blue -gray color on the concave side and a brownish color on the convex side of each arc .

5. When determine the retardation at a selected point in a glass container , rotate the analyzer until the blue-gray color is just displaced by the brownish color at the selected point of grading . Convert the angle of rotation of the analyzer to the apparent temper number as follows :

Apparent Temper Number | Analyzer Rotation Angle (°) |

1 | 0.0-7.3 |

2 | 7.4-14.5 |

3 | 14.6-21.8 |

4 | 21.9-29.0 |

5 | 29.1-36.3 |

6 | 36.4-43.6 |

7 | 43.7-50.8 |

8 | 50.9-58.1 |

9 | 58.2-65.4 |

10 | 65.5-72.6 |

Note : 1°of rotation of the analyzer is equivalent to about 3.14nm optical retardation when using a tungsten filament white light source having an effective wavelength of 565 nm .