PMMA is a polymer obtained by the polymerization of acrylic acid and its esters, which is collectively referred to as acrylic resin, and the corresponding plastics are collectively referred to as polyacrylic plastics. Among them, polymethyl methacrylate is the most widely used. The abbreviation code of polymethyl methacrylate is PMMA, commonly known as plexiglass, which is by far the most excellent synthetic transparent material.

PMMA has the advantages of light weight, low price and easy molding. Its molding methods include casting, injection molding, machining, thermoforming, etc. In particular, injection molding can be mass-produced, with simple process and low cost. Therefore, its application is becoming more and more extensive, and it is widely used in instrumentation parts, automobile lights, optical lenses, transparent pipes and so on.

Acrylic in the field of digital products: it can be used in digital photo frames, as the shell of digital photo frames and so on. Acrylic architectural applications: shop windows, soundproof doors and windows, lighting covers, telephone booths, decorative color mirrors, etc. Acrylic advertising applications: light boxes, signs, signs, display stands, etc. Transportation applications: trains, car mirrors, car lenses, etc. Acrylic medical applications: baby incubators, various surgical medical instruments Civilian products: handicrafts, cosmetic mirrors, brackets, aquariums, toy mirrors, etc. Acrylic industrial applications: instrument panel and cover, etc. Acrylic lighting applications: fluorescent lamps, chandeliers, street lampshades LED reflectors, acrylic reflectors, etc.

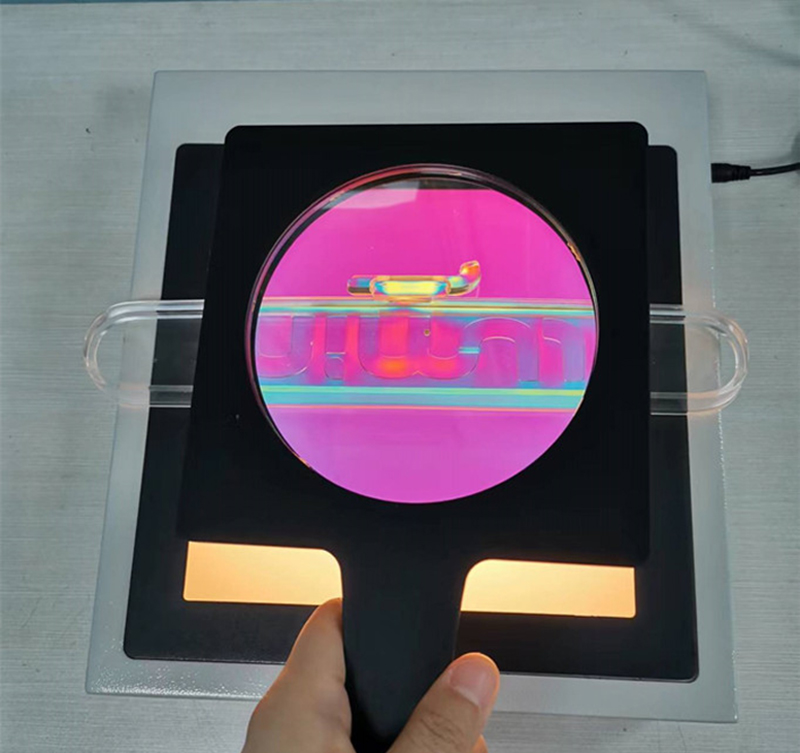

The stress meter adopts the principle of polarized light, which can qualitatively observe and analyze the internal stress of transparent acrylic products, or accurately measure the stress of products through the Senarmont compensation method. It is convenient for users to control the stress of their products in a timely and effective manner, which helps to ensure and improve product quality.